Nano TiO2 properties and photocatalytic properties

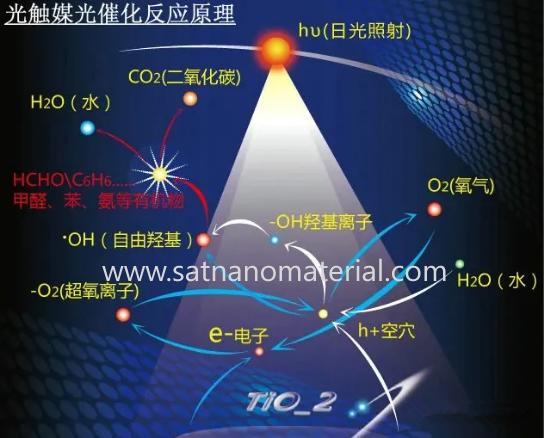

Nano titanium dioxide has the characteristics of small size effect, high specific surface effect and high chemical activity of nano materials, and has high photocatalytic performance. Nano titanium dioxide is popular for its advantages such as low price, suitable forbidden band width, large specific surface area, high chemical stability, strong redox ability, no secondary pollution and reusability.The photocatalytic properties of titanium dioxide are determined by its special energy band structure. Under the action of ultraviolet light, the valence band electrons of titanium dioxide are excited to the conduction band to produce highly active electrons—hole pairs, which can be captured by different points after being transferred to the surface of the body. The oxygen and water in the air are activated to generate active oxygen free radicals (0j-) and (on.) free radicals 121,0 and react with H+ to generate H02- free radicals. HO2-radical and OH·radical hydroxyl have high reactivity. When pollutants are adsorbed on the surface of the base, they will combine with free electrons and holes to cause an oxidation reaction. Thereby decomposing pollutants.

How to improve the photocatalytic effect of nano-titanium dioxide?

Nano-titanium dioxide is widely used in the field of environmental protection, but due to its own narrow conduction band width and easy recombination of electrons to holes, the photocatalytic activity of TiO2 needs to be improved. Generally, the photocatalytic activity of TiO2 can be improved by doping transition metal elements, supporting, synergistic catalysis, surface treatment, etc.

Some scholars doped titanium dioxide with a mass fraction of 0.05% Fe. The catalytic activity is 1.36 times higher than that of pure titanium dioxide. The addition of iron in titanium dioxide with 0.1660% makes the photocatalytic reduction of organic matter in gasoline reach 98%. Under the same conditions, the titanium dioxide catalyst doped with alum increased the degradation rate of H2S by 63%.

Studies have pointed out that using bamboo charcoal to support titanium dioxide photocatalytic degradation of phenol, which significantly increases the degradation rate; using Fe as a magnetic carrier and coated with nanometer titanium dioxide composite powder to make a magnetic suspension supported catalyst that not only has the high efficiency of suspended photocatalyst, but also can be used. Its magnetism overcomes the difficulty of reclaiming suspended catalysts.

Adding the photosensitizer Rhodamine B can increase the utilization rate of TiO2 to light energy, and the heat treatment of TiO2 with reducing gas can produce more Ti3+ on its surface. A suitable ratio of titanium hydroxyl and Ti3+ is formed on the surface of TiO2, which promotes the effective separation of electrons and holes and the transfer of interfacial charge, thereby improving the photocatalytic activity.

SAT NANO can supply high purity nano titanium dioxide tio2 powder 5nm, 5-10nm and 50nm, if you have any enquiry, please feel free to contact us at admin@satnano.com

评论

发表评论