Due to the influence of diseases, aging, frequent traffic accidents and other factors, the number of cases of bone injury has increased year by year. According to statistics, there are 3 million orthopedic cases every year in China, and the demand for bone substitute materials is increasing. In recent years, bone substitute materials represented by hydroxyapatite have gradually become the darling of clinical application.

Hydroxyapatite is a major component of vertebrate bones and teeth and has good biological activity and biocompatibility. Compared with traditional metal (stainless steel, titanium alloy) and ceramic (alumina, silicon nitride) bone substitute materials, hydroxyapatite is not only highly resistant to corrosion and osteoinductive, but also its degradation in vivo is eliminated. The security risks of the former. At present, the research on hydroxyapatite in bone substitute materials mainly focuses on two aspects, hydroxyapatite coating and human bone bionic regeneration materials.

Hydroxyapatite is a major component of vertebrate bones and teeth and has good biological activity and biocompatibility. Compared with traditional metal (stainless steel, titanium alloy) and ceramic (alumina, silicon nitride) bone substitute materials, hydroxyapatite is not only highly resistant to corrosion and osteoinductive, but also its degradation in vivo is eliminated. The security risks of the former. At present, the research on hydroxyapatite in bone substitute materials mainly focuses on two aspects, hydroxyapatite coating and human bone bionic regeneration materials.

The hydroxyapatite coating refers to a hard tissue implant material prepared by coating hydroxyapatite on the surface thereof by using a titanium alloy as a substrate. After the material is implanted into the human body, the titanium alloy can provide sufficient mechanical strength. The surface of the hydroxyapatite coating is easy to combine with the human bone, induce new bone formation on the human bone surface, and generally induce new bone formation in a few months. . Hydroxyapatite coating prepared by plasma spraying technology, Shanghai Institute of Ceramics, Chinese Academy of Sciences, with high bonding strength and good biological activity, and has been applied to artificial hip joints and other hydroxyapatite prepared to date. The coated implant has been used for more than 70,000, and has achieved good clinical results, as shown in Figure 1. However, the hydroxyapatite coating has the disadvantage of insufficient binding force, so that the phenomenon of peeling off of the coating after implantation in the body, the solution to this problem is still being explored.

Figure 1. Partial clinical application of hydroxyapatite-coated bone substitute materials and in vivo osteogenesis experiments. (a) Hydroxyapatite coated artificial hip joint; (b) After 1 month of implantation, new bone is formed and filled with pores between the coating and bone tissue; (c) After 3 months of implantation, new bone is matured Replacement of bone tissue.

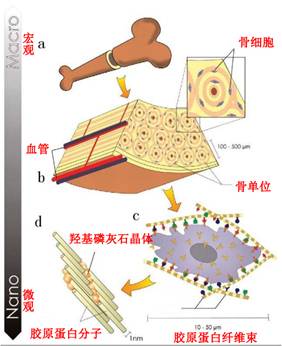

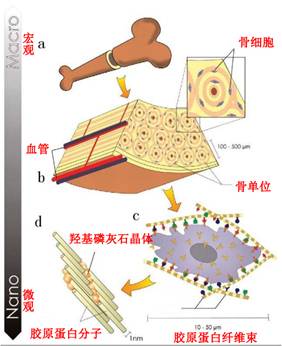

Human bone biomimetic regeneration material refers to the formation environment of natural bone in vitro, and nano-hydroxyapatite crystals of the same size as natural bone are obtained by nanotechnology, and combined with collagen, at different scales (micro and macro) A new composite of ingredients, structures and functions that are realistic and natural. From high-resolution electron microscopy and atomic force magnifying glass analysis, the human skeleton has a very delicate structure: a bundle of collagen and a layer of nano-scale hydroxyapatite crystals, which are extremely "inlaid" in an orderly and orderly manner. 2 is shown. This multi-layer composite self-assembled structure also allows the bone to have both hardness and bending resistance, so the special structural composition of the human bone can theoretically achieve the biological activity and mechanical compatibility matched with the human bone. In addition to this, the presence of collagen makes this bionic bone substitute easy to bond quickly to autologous bone tissue. At present, research on this aspect is still in progress. Because it is difficult for the outside world to accurately imitate the osteogenesis environment in the body, the difficulty of human bone bionics is still very large. Because the cortical bone and cancellous bone in the bone bear different roles, there are still some differences in the structural composition, which undoubtedly increases the workload and difficulty of bone bionics.

Human bone biomimetic regeneration material refers to the formation environment of natural bone in vitro, and nano-hydroxyapatite crystals of the same size as natural bone are obtained by nanotechnology, and combined with collagen, at different scales (micro and macro) A new composite of ingredients, structures and functions that are realistic and natural. From high-resolution electron microscopy and atomic force magnifying glass analysis, the human skeleton has a very delicate structure: a bundle of collagen and a layer of nano-scale hydroxyapatite crystals, which are extremely "inlaid" in an orderly and orderly manner. 2 is shown. This multi-layer composite self-assembled structure also allows the bone to have both hardness and bending resistance, so the special structural composition of the human bone can theoretically achieve the biological activity and mechanical compatibility matched with the human bone. In addition to this, the presence of collagen makes this bionic bone substitute easy to bond quickly to autologous bone tissue. At present, research on this aspect is still in progress. Because it is difficult for the outside world to accurately imitate the osteogenesis environment in the body, the difficulty of human bone bionics is still very large. Because the cortical bone and cancellous bone in the bone bear different roles, there are still some differences in the structural composition, which undoubtedly increases the workload and difficulty of bone bionics.

Whether it is hydroxyapatite coating or human bone biomimetic recycled material, hydroxyapatite is the key to bone substitute material, which gives bone compressive strength and is the main force of bone tissue. In addition, its ability to induce new bone formation is unmatched by other materials. Although the research of bone substitute materials is difficult, with the continuous penetration of nanometers and biotechnology in the field of medical materials, we believe that in the near future, patients will be able to see the dawn of “broken bone regeneration”.

评论

发表评论